Standards

EN 388

The Personal Protective Equipment at Work Regulations (SI1992/2966) require employers to provide their employees with appropriate Personal Protective Equipment (PPE). Protective gloves which are classified as PPE must be CE marked.

To assist in the selection of PPE, the Personal Protective Equipment Directive (89/686/EEC) is written such that safety equipment is categorised. This categorisation enables Safety Personnel to select the appropriate PPE to match the hazards and risks identified during Health and Safety Audits. In addition, the properties of protective gloves are described by a range of European Standards, and gloves must comply with relevant standards.

General Requirements of EN420

EN420 defines the general requirements for most types of protective gloves:

- Product and packaging information and marking

- Design and construction

- Fitness for the purpose

- Sizing

- Comfort and efficiency

- Storage

SUMMARY OF TESTS INVOVED IN EN388 -2003

EN388 is a European standard designed to assess the performance of a fabric or layers of fabric for their ability to resist heavy rubbing, cutting by a blade or sharp object, tearing, and puncture by a pointed object. The test procedure includes a separate test for each of these properties, and a performance level is awarded according to each test result, for example a material with an abrasion resistance of between 100 and 500 cycles would be awarded level 1.

The minimum test results required to achieve the various performance levels are listed in the table below. On labels showing that when a garment has been approved for CE marking to EN388 standard these test levels are quoted as four numbers below the EN388 pictogram, the numbers are always shown in the order in which the tests are described below.

Please note the geometric progression between the minimum results required to meet the increasing performance levels. This means, for example, that the increase in test performance required to improve from blade cut index level 4 to index level 5 is eight times that needed to improve from level 1 to level 2. Please also note that where multiple layer materials are involved the abrasion and tear resistance levels are derived form the most resistant of the individual layers, not the combined assembly. Blade cut resistance is the only parameter where a performance level 5 is awarded.

| TEST/PROPERTY | PERFORMANCE LEVEL | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Abrasion Resistance-cycles | 100 | 500 | 5000 | 8000 | - |

| Blade Cut Resistance-cut index | 1.2 | 2.5 | 5.0 | 10.0 | 20.0 |

| Tear Resistance-Newtons | 10 | 25 | 50 | 70 | - |

| Puncture Resistance-Newtons | 20 | 60 | 100 | 150 | - |

EN388, 6.1 - Abrasion resistance

This test is carried out using an instrument known as a Martindale tester in which the material to be tested is placed on a bed and a rubbing head of fixed size and weight, covered with a standard abrasive material, is moved in a circular motion over the test specimen. Four samples of the material are tested and the test result is the number of cycles required to rub through the material. The standard abrasive material used in this test is severe in action, it is unusual for textile materials to withstand the 2000 cycles required to meet performance level 3.

The performance level of a single material is decided by the lowest result of the four tests in accordance with the table above. For multiple layer materials each layer is tested separately, the performance level is based on the lowest individual result of the most resistant material.

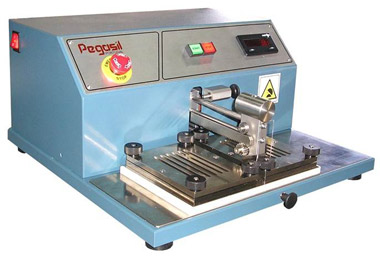

EN388, 6.2 - Blade cut resistance

The instrument used for this test consists of a circular, free rotating blade, under pressure from a standard weight, which is moved backwards and forwards over the surface of the test material over a fixed stroke length. The test result is the number of cycles taken for the blade to cut through the material. To take the sharpness of the blade into account the test is performed using a standard material before and after testing the sample, the mean of these two tests on the standard material is defined as blade cut index 1. The test result is the ratio of the number of cycles required to cut through the sample to the number of cycles required to give blade cut index 1.

Where multiple layer materials are involved the layers are assembled and tested as they would be in the garment. Two test samples are selected, each sample is tested five times and a mean blade cut index calculated from the five tests. The performance level is awarded in accordance with the lower mean blade cut index of the two samples.

EN388, 6.3 - Tear resistance

In this test a sample of material to be tested is prepared in a standard way and clamped in the jaws of a strength testing machine. The jaws are moved apart at constant speed and the force needed to tear the material measured. For single materials the performance level is given by the lowest result of four tests. For multiple layer items each layer is tested separately, four tests carried out on each material. The performance level is based on the lowest individual result of the most tear resistant material.

EN388, 6.4 - Puncture resistance

This test uses a standard, rounded point which is pushed through the material at a fixed speed and the force required for the point to penetrate through the material is measured. Where multiple layer materials are involved the layers are assembled and tested as they would be in the garment. Performance levels are awarded in accordance with the lowest of four test results.

EN340

Since 2003 all items that are submitted for CE marking as personal protection equipment must also be examined in accordance with this general standard as well as the specific standard required. EN340 defines toxic, carcinogenic and other materials prohibited from use, or which are allowed to be present only below set levels, in products sold in the European Union. The standard specifies tests that must be carried out on different categories of material. The two main tests for textile materials are for the pH value (highly acid or alkaline) and the presence of banned Azo dyes.